Increase the performance of your biogas plant with biofermat granules

while

simultaneously purifying the gas biologically

THE RAW MATERIAL

In the production of biofermat granules, only the brown algae species "Ascophyllum nodosum" is used. This algae is harvested by boat in the North Atlantic and then dried in a facility using geothermal heat. At our plant in Dahlenburg, we use special extraction methods to produce alginates for a wide variety of applications. In the case of biofermat granules, these alginates are bound with bentonite.

REQUEST CONSULTATION

058 51 - 15 64

nfschlz-hrmsnd

THE PRODUCT

biofermat Granules are development to achieve greater profits from your biogas plant. With the help of biofermat Granules, the microbial activity in your plant is greatly increased. The biological processes within the reactor run better and faster.

| Anwendung | |

|---|---|

| Basic inoculation, daily requirement | Up to 200 g of biofermat granules per m³ of fermenter |

| content Gas purification | 200-300 g of biofermat granules per m³ of feed mass |

| Yield increase | Yield increase: 400-500 g of biofermat granules per m³ of feed mass |

| Packaging | 25 kg in a plastic bag |

ADVANTAGES

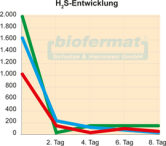

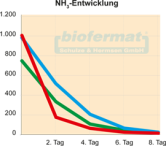

For every biogas reactor operator, H2S production is a costly factor. With the help of biofermat granules, it is possible to significantly reduce the amount of this gas. The ammonia content in the gas typically drops to zero ppm. Multiple tests have clearly demonstrated this. Users repeatedly point out that the well-known nutrient properties of our algae preparations are not lost in the fermenter but remain active in the soil.

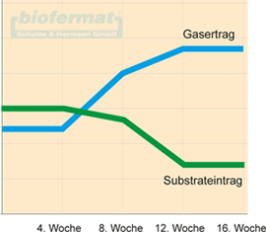

A positive effect on soil biology and plants is evident. Especially today, a balanced carbon value is important. Increased root mass contributes to this. The nitrogen and sulfur not detected in the gas as NH3 or H2S remain in the digestate, making it available to plants, thus providing a portion of the nutrients for soil and plants. The development of the costs for renewable resources and gas purification has reached a point where it is increasingly important to calculate accurately and minimize the risks of high operating costs.

biofermat granules can help you to reduce raw material costs. The more active and stable biology ensures optimal utilization of the materials used.

The following advantages speak in favor of using biofermat granules:

Significantly

improved gas yield

More active biology

More homogeneous fermenter contents

Dissolution of sinking layers and floating layers

Hydrogen sulfide in the gas is significantly reduced

No ammonia in the gas

Reduced exhaust emissions

Longer oil change intervals

Significantly less air infiltration required

Sulfur and nitrogen in the substrate are available to plants

Basic supply of micronutrients

Lower power consumption of the agitators

Optimization of the fermentation proces

The special nutrient media in biofermat granules cause more intensive degradation of the supplied organic matter. The bound clay minerals provide an increased surface area and supply micronutrients to the fermenter.